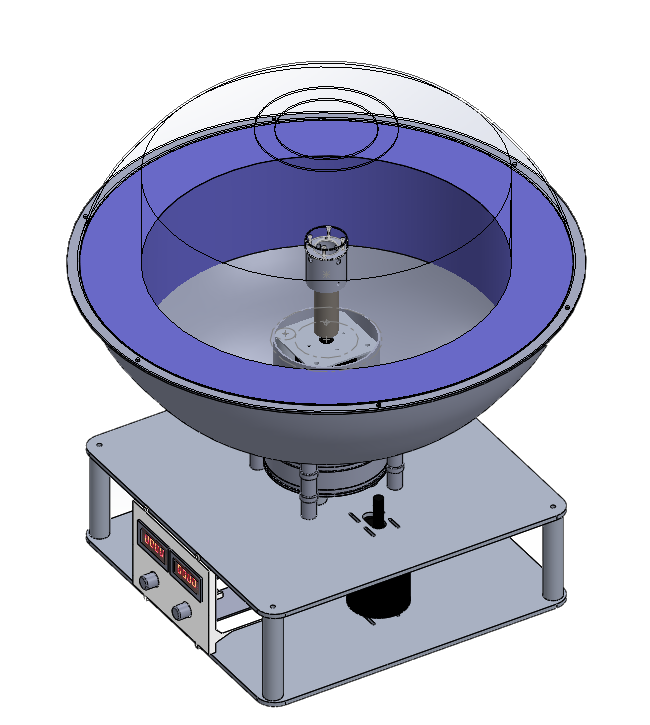

Photo Taken On Study Abroad in Romanian Underground Hydroelectric Plant

Latest Project Updates

Project Goals V1.0

October 23, 2024

Current Project Goals

- [COMPLETED] Containerize Turtlebot3_bringup and RFID capture code

- Allow for easier development with docker images saved on server registry

- [IN PROGRESS] Containerize rtabmap in VSCode dev container for easier development

- By doing this, I’ll have a backup image / baseline to work off of.

- [COMPLETED] Create node to output RFID detection events as landmarks

- Tie the RFID tag ID to the location transform from the map frame at the instant of detection

- [IN PROGRESS] Integrate RFID detection events into rtabmap as landmarks

- Save detections with the map and use them for relocalization

Landmarks

November 19, 2024

Today’s Summary:

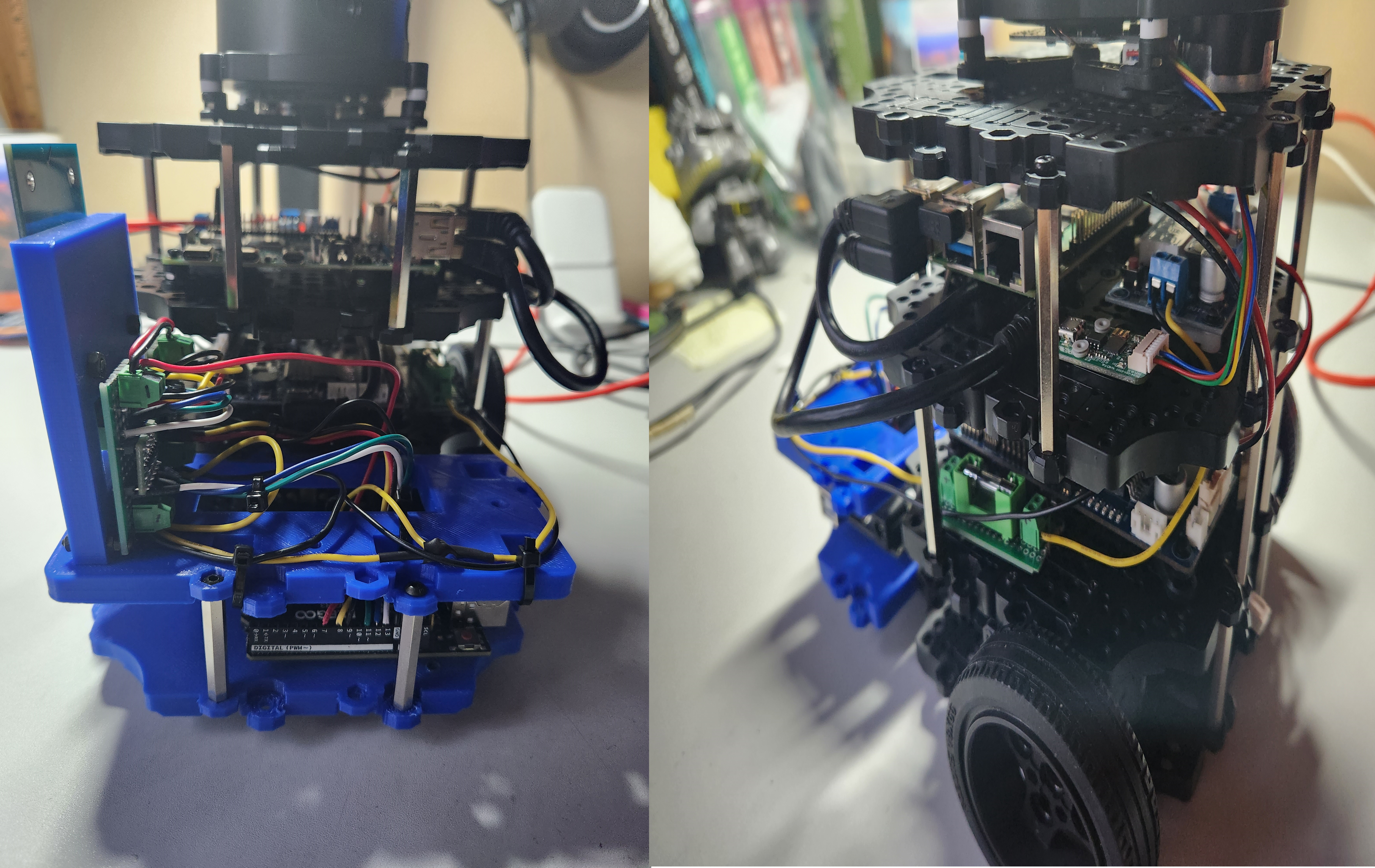

Today I implemented an rfid_landmark node that would publish the transform from the map frame to the PN5180 RFID reader’s frame for rfid detection events. As you can see in the video below, there is a lot of tolerance for that detection, and so the landmark moves with the robot a bit. In addition, you can see that the landmark is preexisting at the beginning of the video but rather than localizing the robot, the detection frame moves itself. This will be addressed soon. Immediate objectives are in the full post.

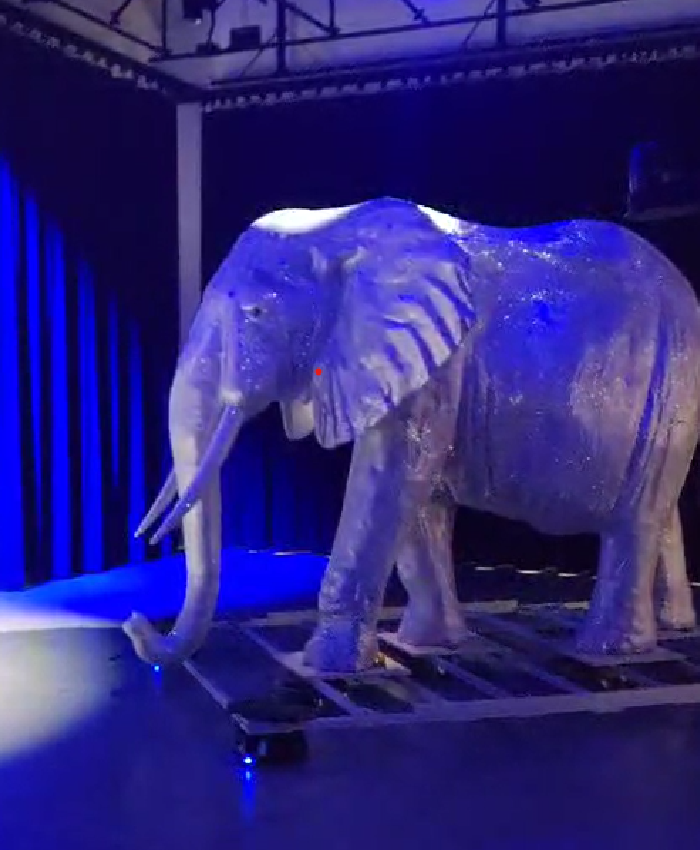

Photo Taken On Deployment in León Mexico

Education

Undergraduate

Mechanical Engineering

Honors College

Rigorous Classes and Research

Robotics Research

SLAM and ROS for Planogram Compliance

Undergraduate Thesis

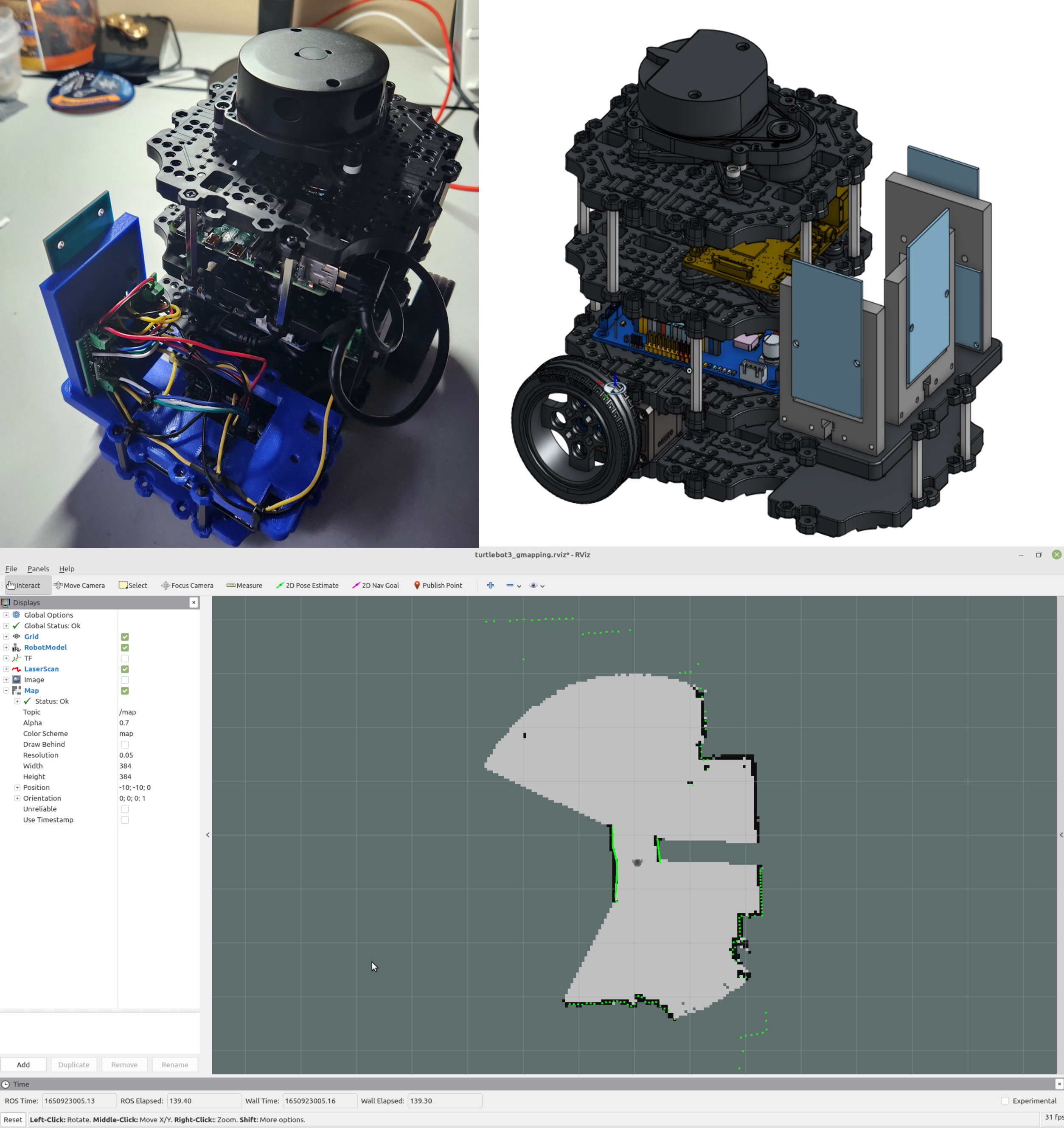

During my undergrad at Georgia Southern University, with the help of my faculty mentor Dr. Alba Flores, I independently pursued robotics research. In reflection, my work was a tremendous amount of self study and literature review but was fundamental to fostering my passion for robotics and in giving me a solid foundation for growth. Through published works, online resources, and textbooks, I was able to teach myself about ROS1 and ROS2 architecture, how a complex system can be discretized, and extensively about Simultaneous Localization and Mapping.

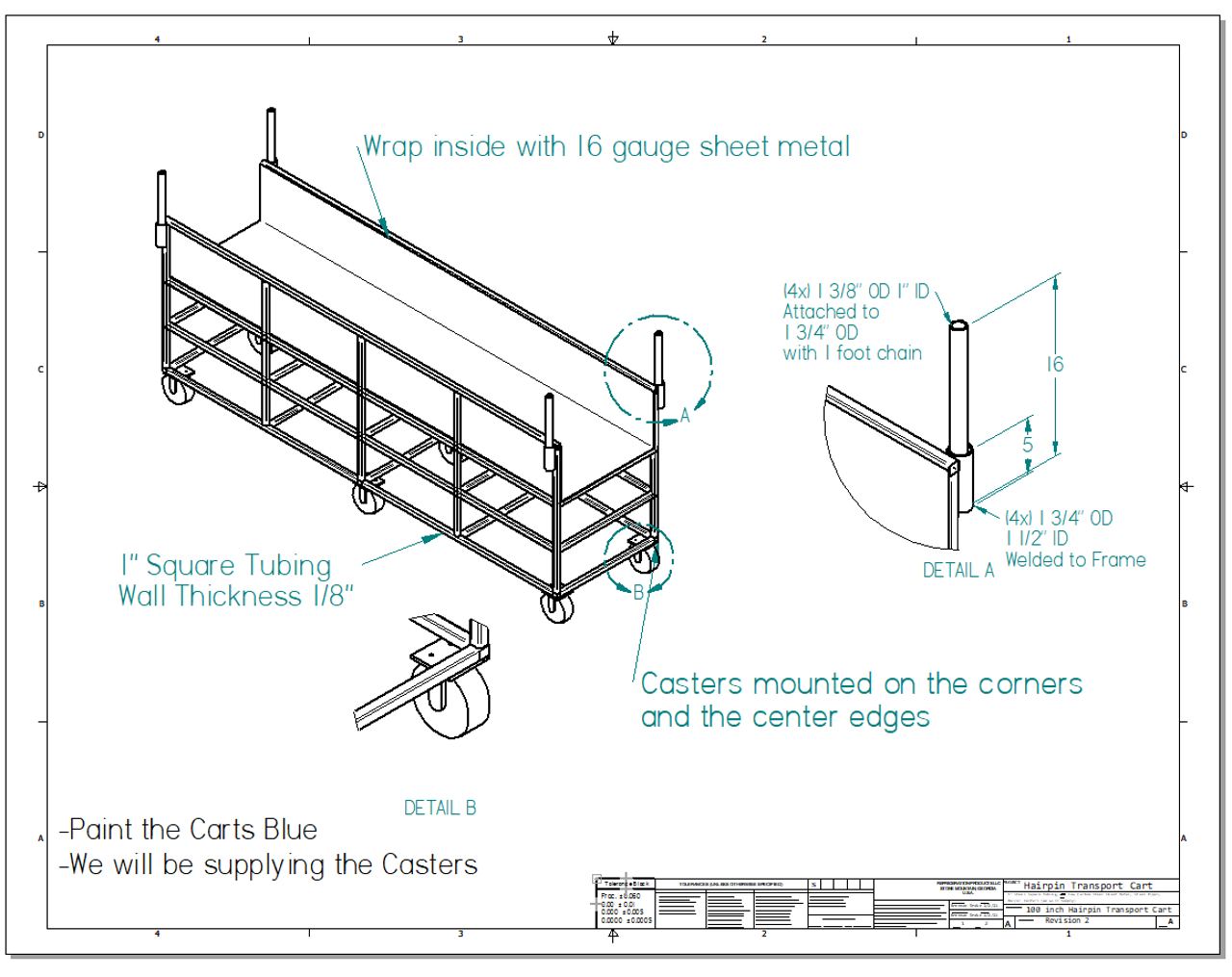

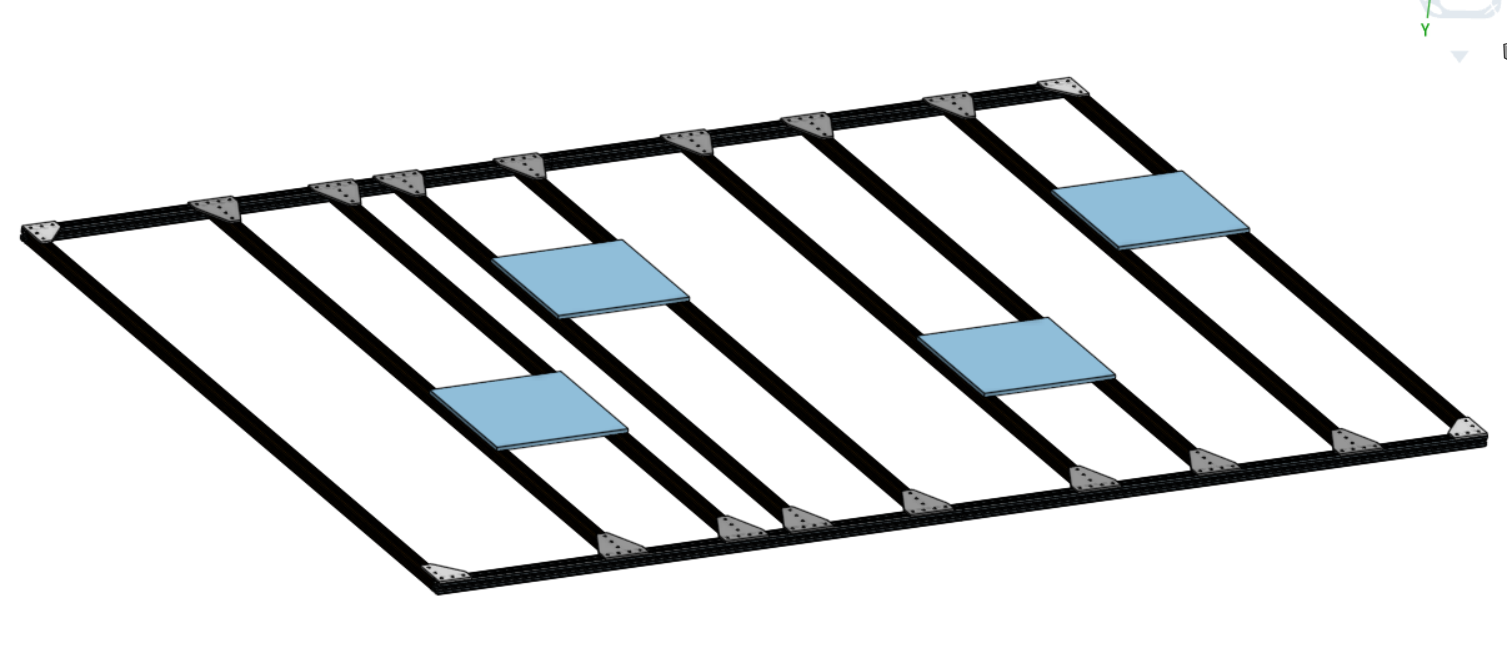

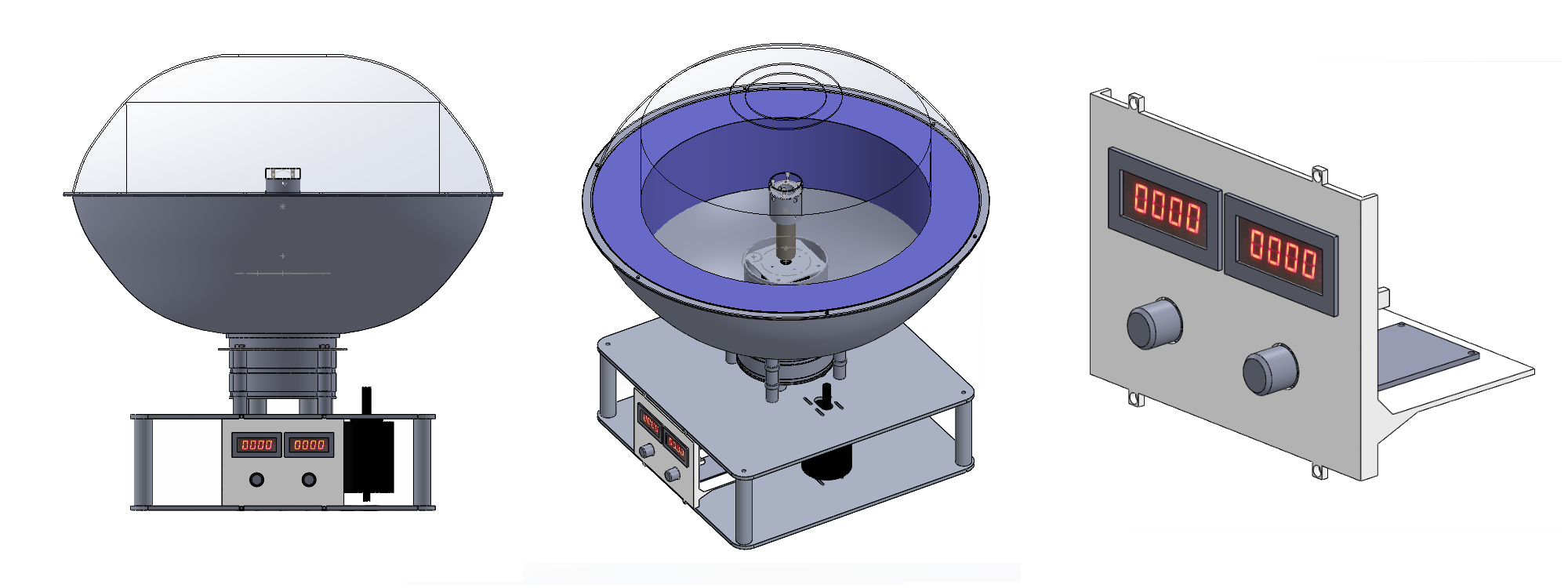

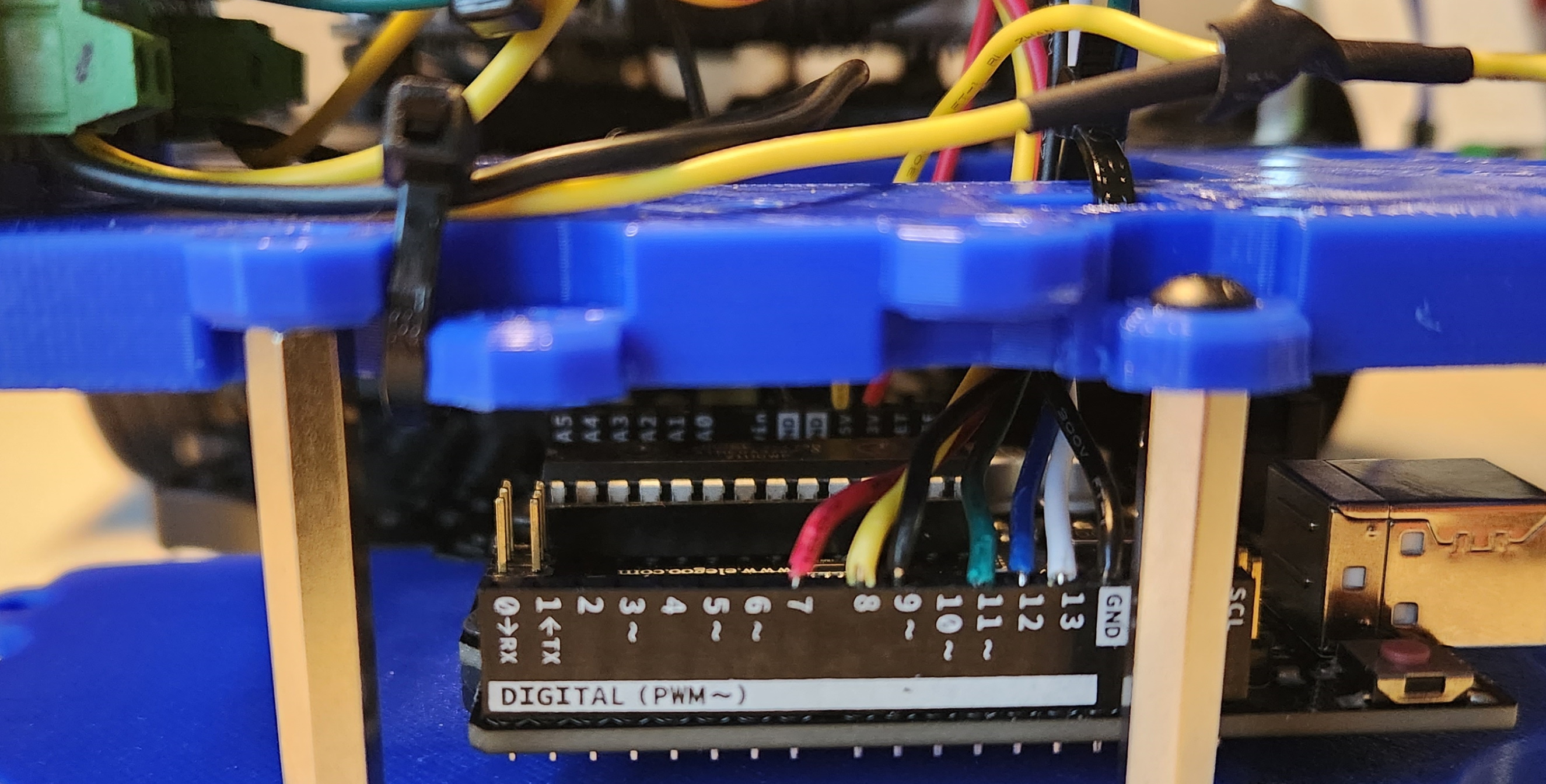

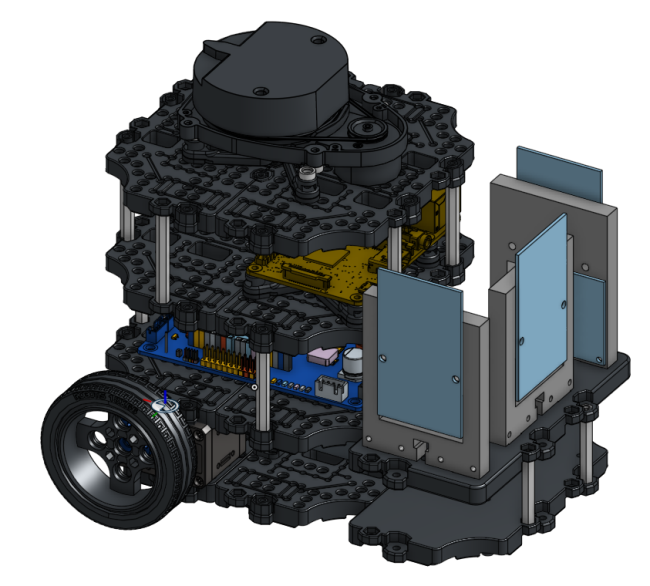

As can be seen in my work below, using a Turtlebot3 system, I fabricated an experimental assembly to integrate PN5180 NFC/RFID reader data into the turtlebot's control system. By the conclusion of my studies, I had completed the experimental assembly with detected RFID tag IDs being published to a ROS topic, and had validated this collection with a small script of motion prompted by specific IDs. I would like to perform more work focused on this field, pertaining to visual SLAM methods, integration of LLM and object recognition, and higher level AI and and machine learning topics.

Photos and videos of the project can be seen in the portfolio section above.

Career

-

January 2021 - April 2021

Manufacturing Engineer

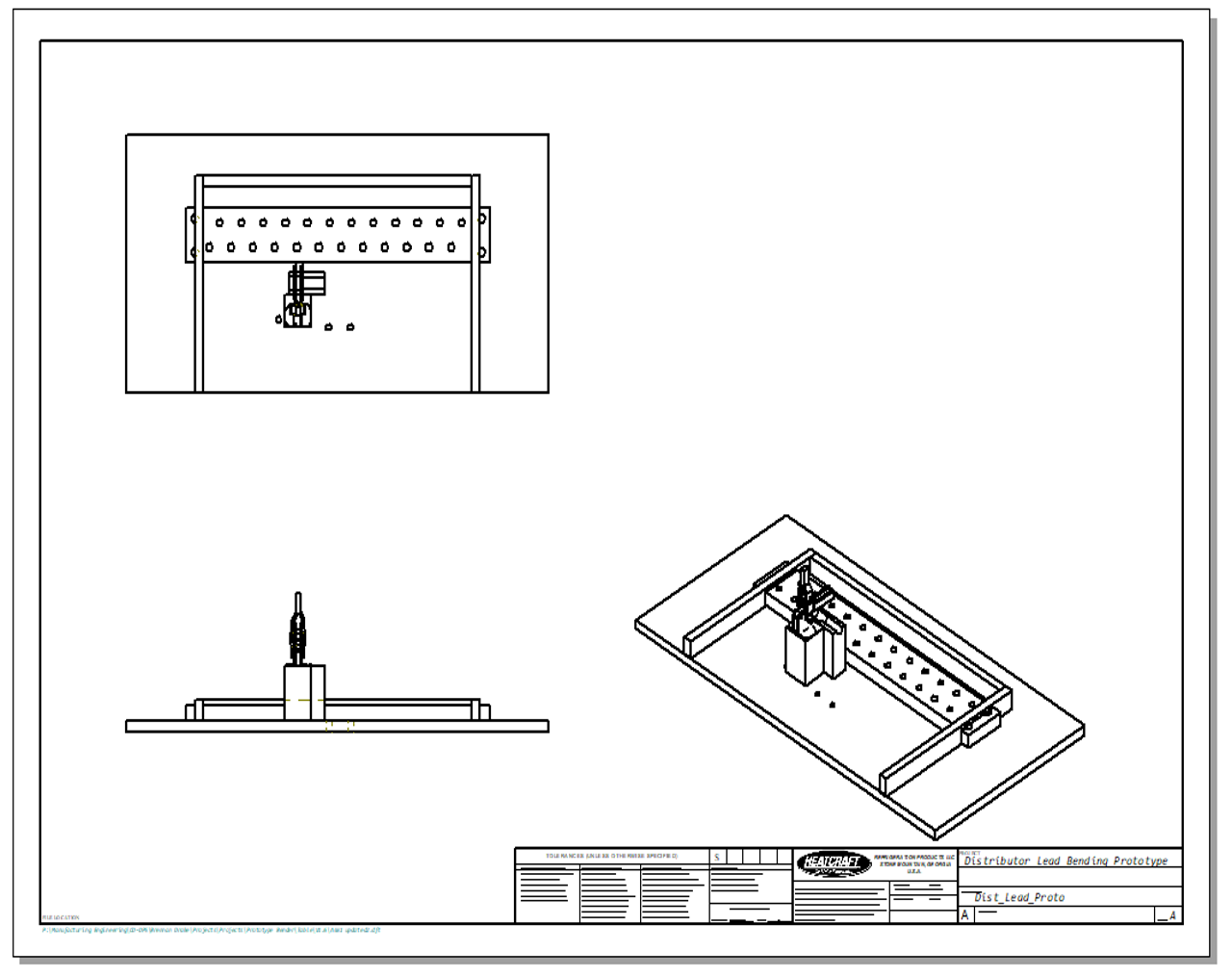

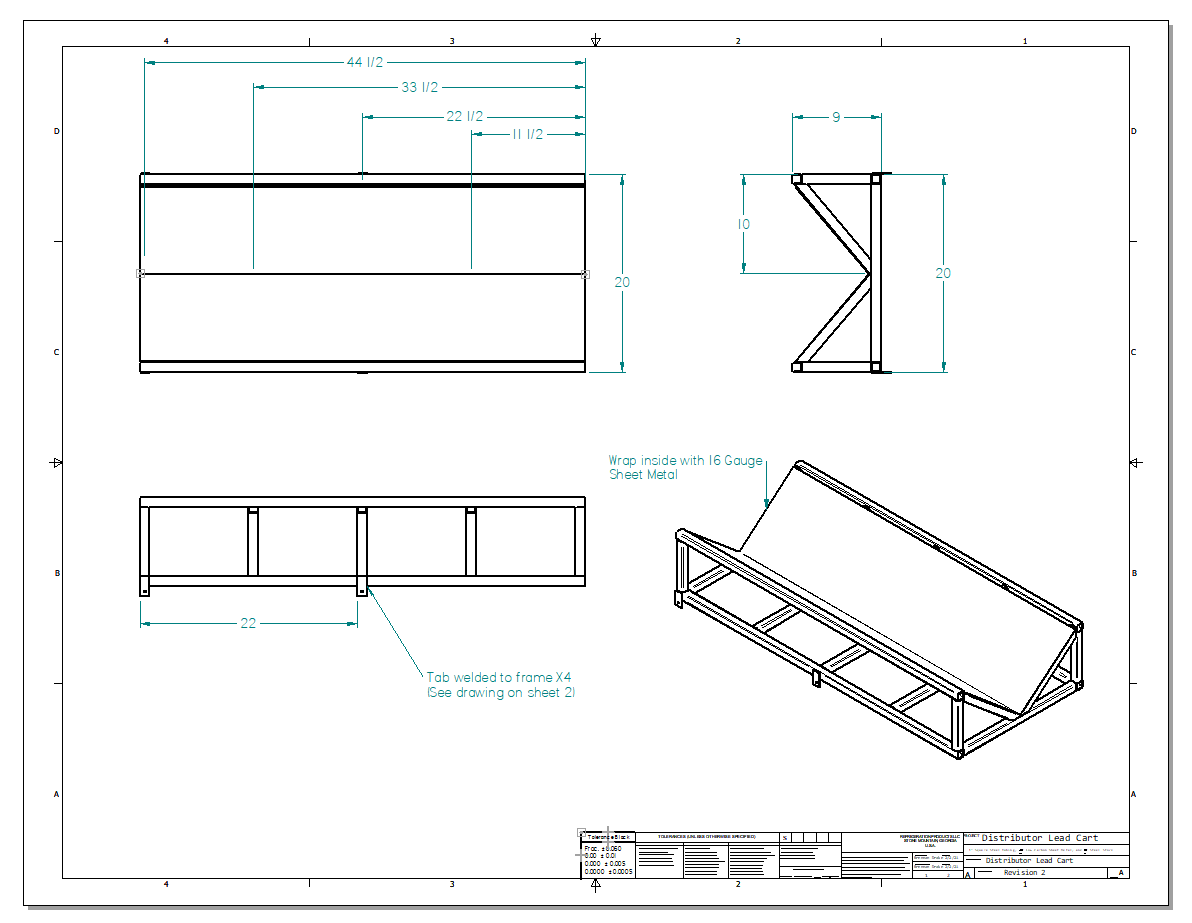

Heatcraft Refrigeration Products

Working as a Manufacturing Engineer in a high volume production environment, I was able to gain exposure to process improvements and continuous improvement work. I primarily helped to design and implement improvements around the plan that would increase productivity, safety, and quality.

-

August 2021 - December 2021

Systems Safety Engineer

Gulfstream Aerospace

One area I grew working as a Systems Safety Engineer was in reading comprehension of technical documentation. Systems Safety Engineers are responsible for making sure that every step of validation, verification, and certification of aircraft systems are documented and thoroughly assessed by the appropriate subject matter experts. I was able to contribute to certification of aircraft by taking responsibility for the lighting system which entailed drafting and/or developing System Safety Assessment, Fault Hazard Assessment, and Fault Tree analysis documents.

-

May 2022 - August 2022

Adv. Materials Lab Engineer

Gulfstream Aerospace

The advanced materials lab at Gulfstream is responsible for producing shop-aids, prototypes, and experimental test rigs for use around the organization that cannot be produced by other means. In this role, I was able to gain exposure to a variety of different additive manufacturing technologies operation, maintenance, and innerworkings while continually working to make the lab more efficient, safe, and productive.

-

May 2023 - Present

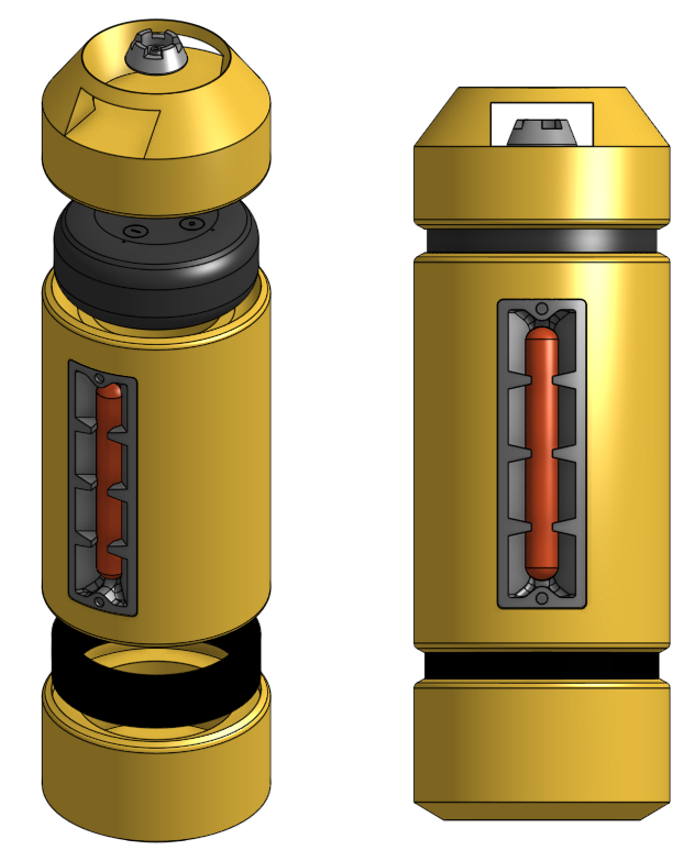

Robotics Deployment Engineer

Wheel.me

Wheel.me is the first robotics company that produces a product allowing customers to turn existing infrastructure into an autonomous mobile robot. As a deployment engineer, my role is to install our solution in customer sites and to be the final point in the feedback loop for development of the product.